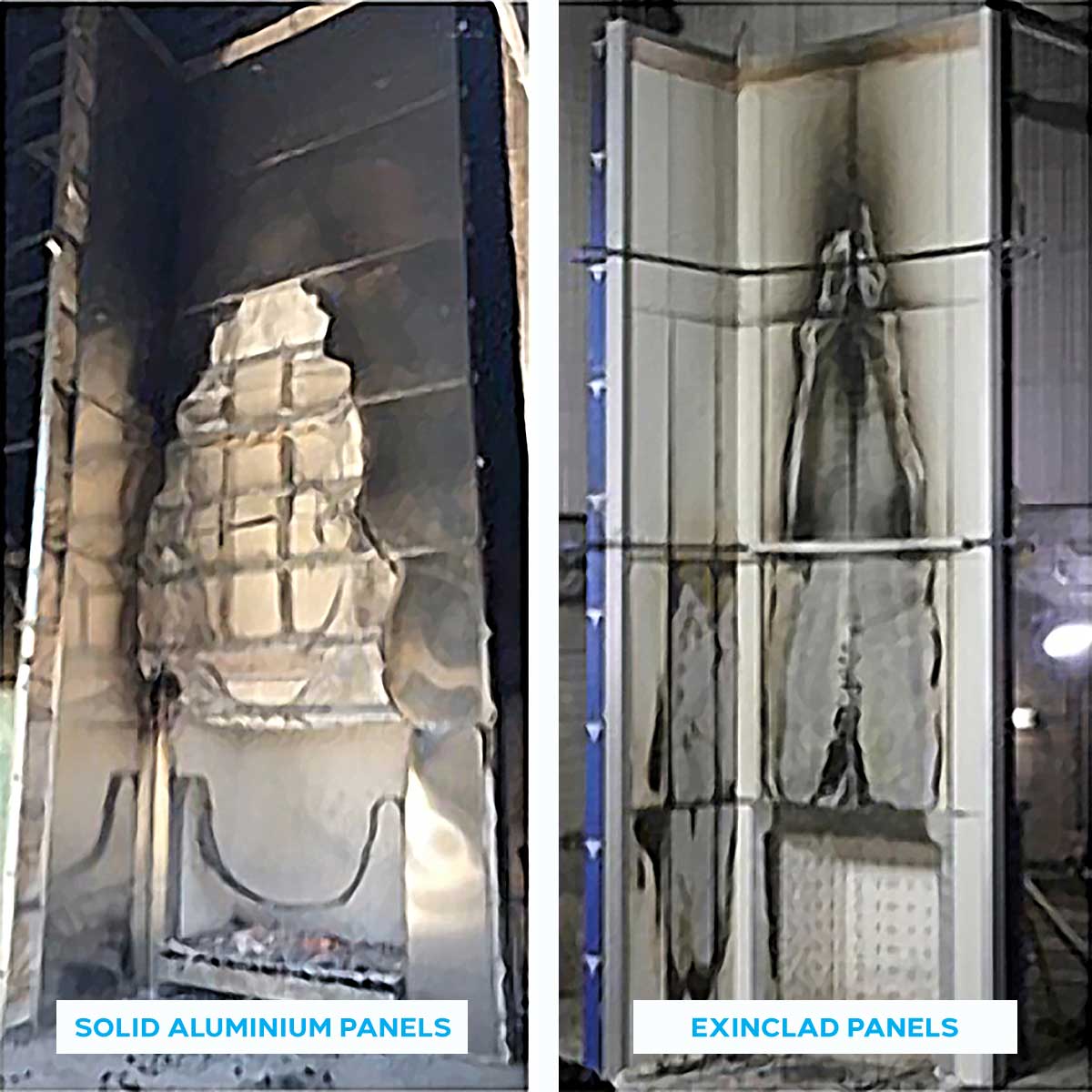

Exinclad's fused steel panels being tested in the CSIRO's NATA accredited laboratory under the AS 5113 full scale fire test regime.

Fire-Proof to withstand in excess of 1000°C

The only metal cladding that does not drop dangerous solid mass debris.

Heat Sink Technology to actively transfer and dissipate thermal energy.

Exinclad harnesses the lightness of aluminium with the strength and durability of steel to form a high-performance, high tensile, fire-proof panel.

The patented combination of chemically fused zinc annealed steel and aluminium utilizes industry-leading Heat Sink Technology to actively transfer and dissipate thermal energy. This uniquely enables Exinclad to disperse heat and resist infernos in excess of 1,000 degrees Celsius.

Patented technology that chemically fuses zinc annealed steel and aluminium to deliver the world’s safest metal cladding product – a high-performance, high-tensile, non-combustible façade panel that can withstand heat and flaming of up to 1,000 degrees Celsius.

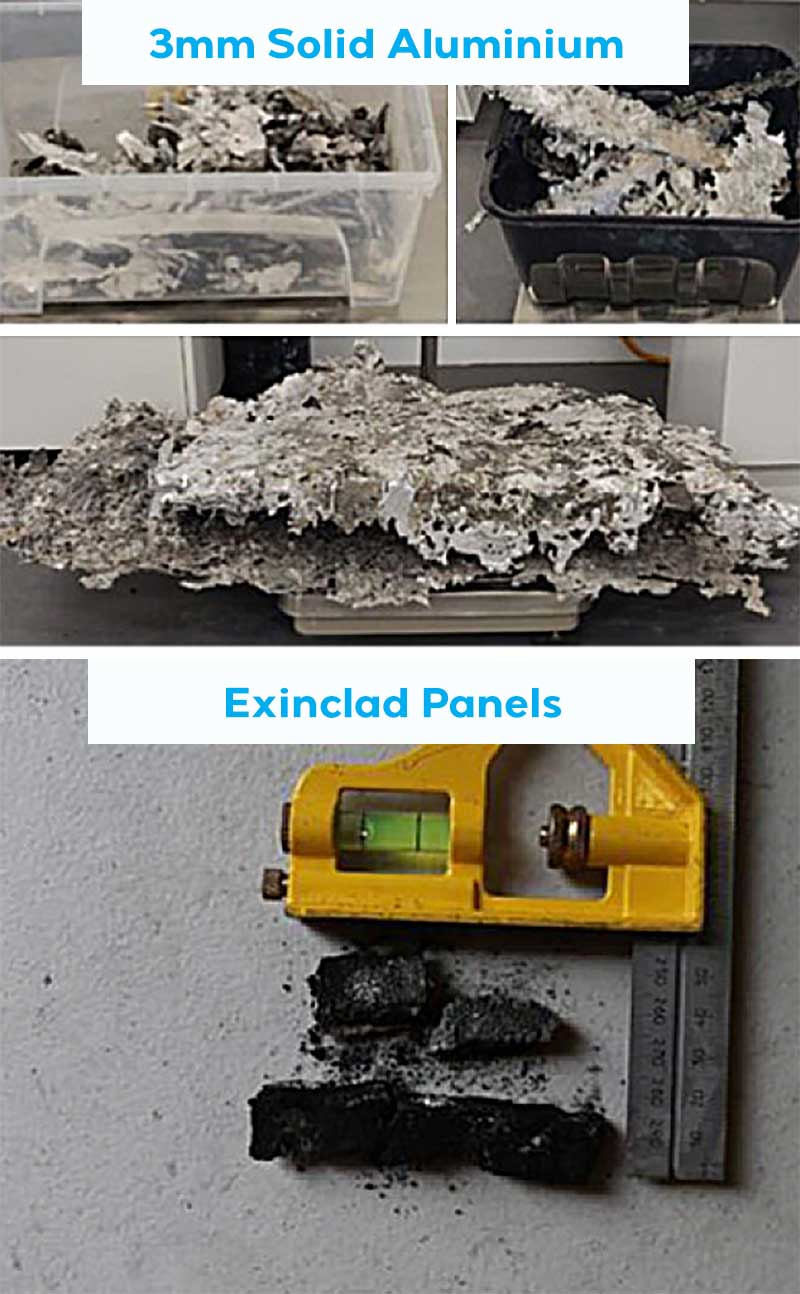

A total mass of debris exceeding 2.0 kg constitutes a failure of the debris criterion of AS 5113-2016.

3mm solid aluminium panel produced a total mass of 46kg (of which one piece weighed 19kg).

The Exinclad panels satisfied this criterion with a total mass of under 100 grams.

Exinclad harnesses the lightness of aluminium with the strength and durability of steel to form a high-performance, high tensile, fire-proof panel.

“No other panel has passed the Debris Criterion of AS5113-2016 full scale fire test.”

“We have been using Aluminium façade materials for over 30 years and Exinclad is the most innovative product we’ve come across in that time.”

“Exinclad outperforms solid aluminium, and is the only aluminium based façade panel I have ever seen that passes the debris criteria of AS5113.”